Welcome to Rolf Kind GmbH

Our mission: to produce more than conventional forgings with forging technology par excellence.

Forging technology "made in Germany" used worldwide

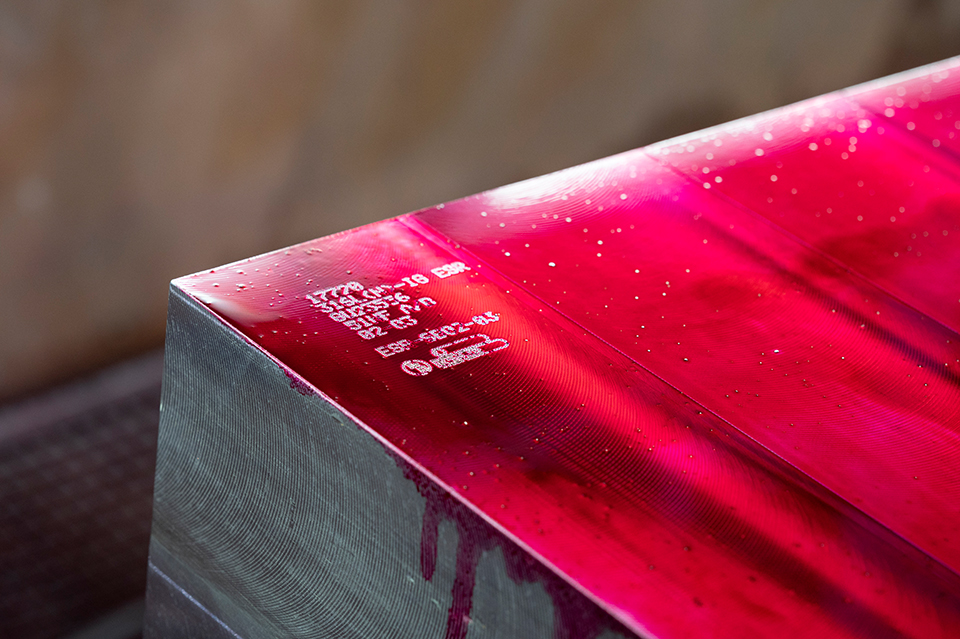

Since its foundation in 1969, Rolf Kind GmbH has set itself one task: To produce excellent forgings and to prove our performance time and again through innovative ideas and highly efficient manufacturing technologies. Our goal is to overcome the limits of conventional forging technology. We offer our customers extremely resilient forgings in high-quality alloys at economical conditions. Rolf Kind GmbH has been a family-run company since its foundation. We have always relied on the complete production chain in the manufacture of our forgings, from the cast ingot to the finished and tested workpiece.

Here, we combine flexible production management with the precision of our internal finishing. This enables us to guarantee the quality that meets our customers' requirements as well as our own high standards. The efficiency of our working methods convinces customers worldwide. As a pure manufacturer of special parts, our Rolf Kind products are in demand as never before in the global economy. From Germany, we export up to 80 percent of our customized forgings all over the world.

The services of Rolf Kind GmbH include

- processing of ingots in nickel-based alloy, high-alloy stainless steels and titanium with weights from 3,000 to 50,000 kg

- Free-form forging on forging presses from 20 MN to 100 MN as well as ring rolling up to 50.000 kg operating weight

- Heat treatment of individual forgings up to a diameter of 4.5 m and a length of 18 m

- Machining in our machinery of lathes, milling machines, boring mills and band saws up to a diameter of 4.5 m and a length of 24 m

- Destructive testing such as ultrasonic, X-ray, dye penetrant and visual inspection, etc.

- Destructive testing in cooperation with accredited laboratories

Forging technology "made in Germany" used worldwide

Here, we combine flexible production management with the precision of our internal finishing. This enables us to guarantee the quality that meets our customers' demands as well as our own high standards.

The efficiency of our way of working convinces customers worldwide. As a pure manufacturer of special parts, our Rolf Kind products are in demand as never before in the global economy. From Germany, we export up to 80 percent of our customized forgings all over the world.

Quality made in Germany.

If manufacturing according to international standards is required, you are on the safe side with our quality management.

For all the innovative spirit we bring to every newly developed forging, product quality is always our top priority. Especially in sectors such as the chemical industry and plant engineering, the smooth functionality of our components has top priority. And last but not least, trouble-free processes ensure increased efficiency and thus help to save costs. Our certified "Level III" personnel are able to supervise the preparation and execution of all destructive and non-destructive tests such as ultrasonic, dye penetrant and visual testing, and guarantee processing in line with requirements.